It is believed that the journey of warehouse management started in ancient times when farmers thought to keep a record of grain from the crop.

All they wanted was to use the record so that they could prevent famine.

With time and technology, the process turned out to be fast and tracking became easier.

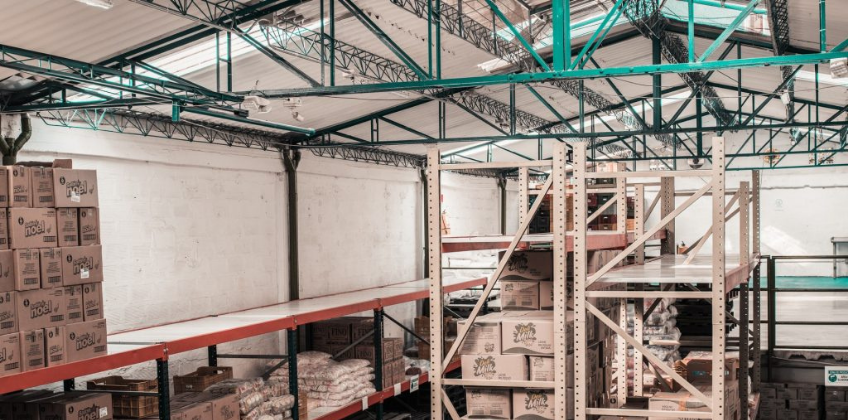

However, the basic concept of warehouse management never changed. Therefore, it can be defined as “managing everyday operations of a warehouse”.

The process includes arranging warehouse and physical inventory management, maintaining appropriate equipment, conditioning of product, managing new product, space management, packaging, stock receiving, and tracking.

Hence, improving overall warehouse performance!

And “an application or software designed to optimize the method of storage by controlling and administrating the operations in a warehouse is known as a warehouse management system”.

This was a glimpse of all the content that we are going to discuss in today’s blog. Let’s first start with understanding the basics of warehouse management systems.

What does a warehouse management system do?

A warehouse management system controls and manages the process of stock storage with the aim of providing consistent availability of the product.

It is a software supporting day to day operations in a warehouse, giving you a centralized system to control the process of storage.

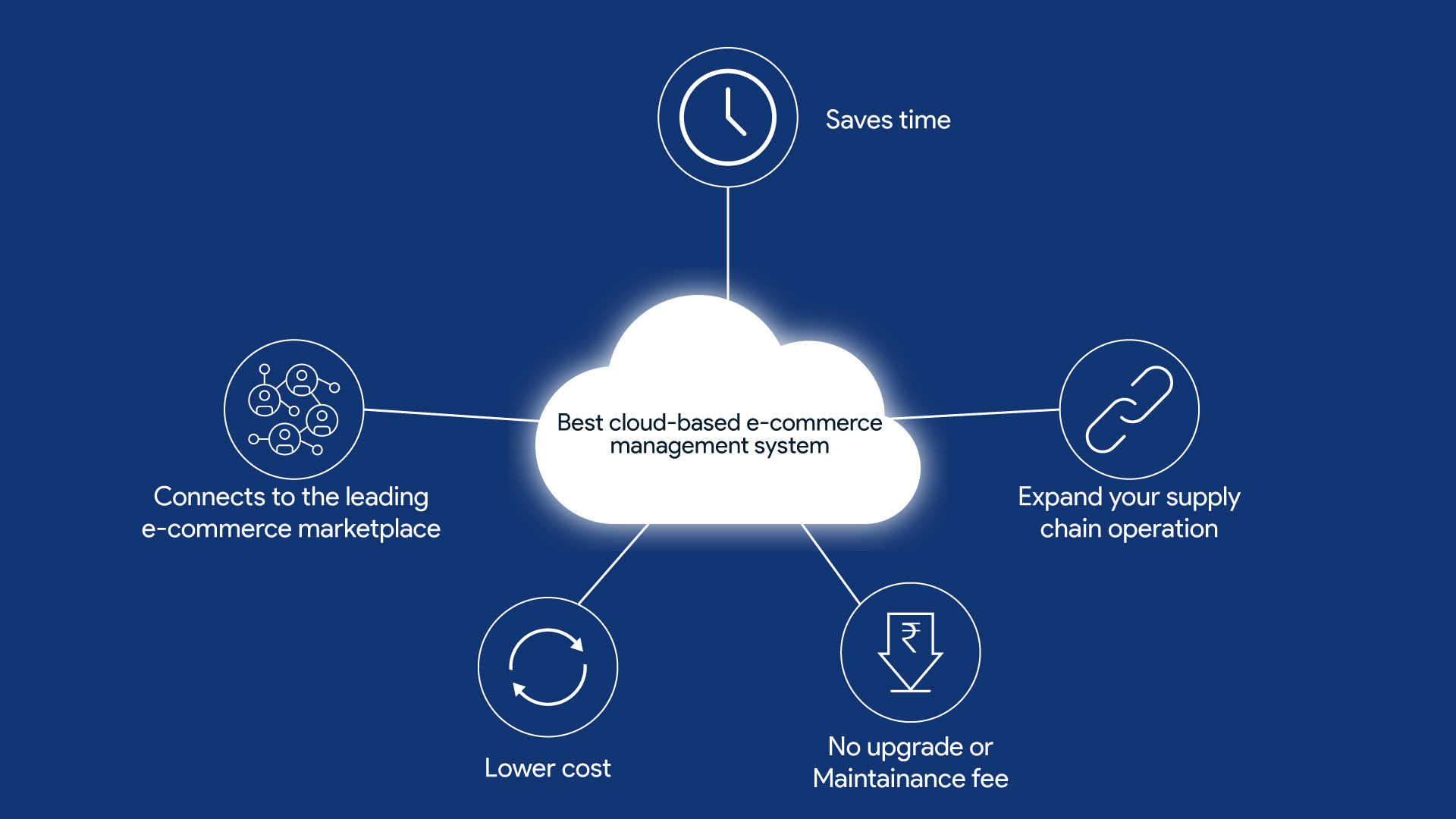

There are many other benefits of using a cloud-based warehouse management system for your business growth.

Benefits of a modern cloud-based warehouse management system

With technically growing nations and advanced customers who mostly prefer digital mediums for all their purchases, it is the right idea to adapt the smartest technology.

Warehouse management process

The process of warehouse management involves the following steps: receiving goods, put away and storage, order picking, packing, and shipping.

All these processes involve certain functions and you can always optimize your functions according to your business needs.

1. Receiving of goods

The process of warehouse management starts with receiving the product and unloading it from the vehicle.

Here you have to ensure that you received the right product, in the right amount and right condition.

Don’t just receive but validate!

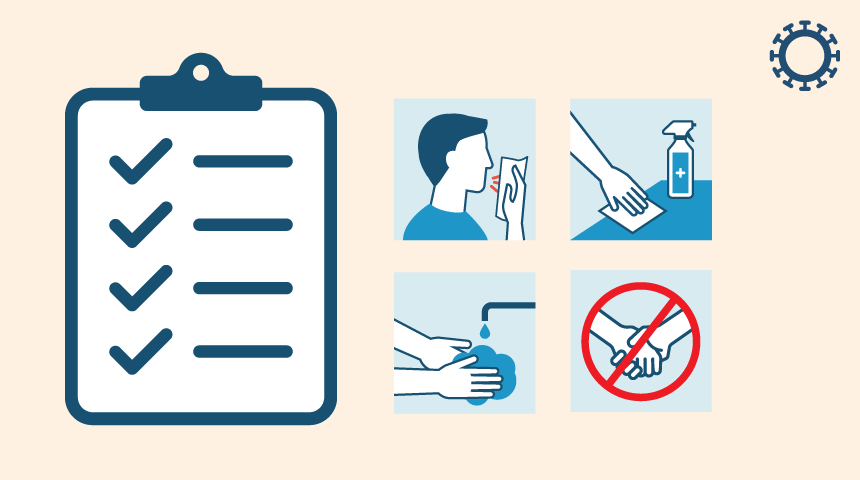

When the shipment arrives, make sure to check and validate the product, which means you have to check the quality of the product.

Quality control here can help you in making further processes smooth. It involves checking the goods you ordered thoroughly and then taking them forward to your inventory.

If any product is damaged, keep it aside and inform about it in real-time.

Unload the products and check if the number of boxes is the same as mentioned in the

delivery shipping notice i.e. you have to check the product count.

Check all the return documents such as invoice and packing slip.

After all these processes are done you have to prepare goods received note mentioning the details of the products you received.

The details include the description, quality, date of receiving, GRN number and so on.

This will help you to make entries in the inventory about the product and you can also cross-check that you received all that you ordered.

Finally, you are ready to arrange the product in your inventory accordingly.

Receiving a new product!

With a growing business, it is quite obvious to expect a frequent rate of new products in inventory.

With new products, you have to play a little wiser!

Remember to mark enough space for newly arrived products in your inventory and guide your team about the product and its handling.

Add necessary labels and barcodes to the product at the time of putting away and don’t forget to update your inventory. As in this way your product will be ready to sell.

2. Put away and storage

Similarly, for every product once received, you have to put away the product in the right, place and keep the product in the best suitable condition.

Doing them right can help you to get the most optimum results in the future.

Make sure to do the “material handling right” for this entire process.

As by handling the product right, there will be less damage leading to more satisfactory delivery and you know the rest.

Use this principle and optimize the process!

“Minimal touches of goods,” the principle states that you should directly put away goods to its final location.

The fewer the touches are, the less will be the probability of product damage.

Also, make sure to do the put-away process on the day you receive stock.

It is often seen that when the new orders arrive, the team turns to be busy working on it. Hence, the priority of that moment is picking and packing.

keeping the new stock aside. And this may negatively affect your warehouse.

The put-away process and storage go hand in hand, once you are ready with where to keep the stock, make sure to consider the storage required by your products.

The conditioning of products must be given a high priority depending upon the needs of the product.

You can also use the ABC tool!

According to this tool, the products get classified into three sections.

1. A Item- These are the high-value products with low sales frequency.

2. B Item- These are moderate value products with moderate sales frequency.

3. C Item- These are low-value products with high sale frequency.

You can keep C items closest to the packaging area and Vice Versa for A item.

You can also categorize the product according to its requirements.

For example, if the product is very heavy, try to place it with the proximity of the door, or if a product is required to be kept at a particular temperature, make sure to place it accordingly.

Rearrange the warehouse with time!

No doubt the process is really time-consuming, but good management is all about investing the right resources at the right time for optimum future results.

Right?

So do not hesitate to rearrange your warehouse according to the need of time.

As there could be some products that are at high demand during summers and during winters no one wants them.

Once the put-away and storage are done to your product, you start getting orders and therefore the process of order picking starts.

3. Order picking

As the name itself signifies its meaning, the process involves picking up the goods as per customers’ demand.

It is found that this process involves the highest percentage of all warehouse operational expenses, comprising 55% of it.

The process of order picking involves selecting the item from the warehouse to satisfy all the independent customer orders.

Therefore, it is recommended for you to follow a smart technical way to analyze the process.

Choosing the right order pick up system involves the requirements of your product by customers.

Since the requirement of every product is different, it is not necessary that one plan will work for all.

So, here are some of its types!

1. Zone picking- In this method, the inventory is divided into zones and the order picker will only work for one specific zone.

The process of zone picking works best for businesses with high order volumes and multiple daily ships.

The process may take more days for shipping as products are passed around in the warehouse.

2. Batch picking- A picking process that mostly works well for any business, that follows the motive to fast order fulfillment.

In this process, instead of working for a particular zone.

The team works for the orders to pick them up in batch and move for the packaging process.

The process is considered best for businesses with high order volume and has a common SKU.

3. Discrete picking or single picking- In this process, the team works for one order at a time, the team will only move to the next order when the first order is entirely complete.

This is usually done by small businesses, businesses with a small team or business working for heavy goods.

4. Wave picking- It is similar to discrete or single picking process, the only difference is, in this process orders from all the zones are picked and orders are then sorted as per requirement.

So these are all the picking techniques, you can choose or follow any of them.

But don’t forget to move to the next, till you find the best!

4. Packing the product

Once the product is picked, packing is to be done for further shipment.

All you need to be definite about is, you are shipping the right product to the right customer and of course with the right packaging.

Packing is much more than just tossing your products in a carton.

You have to be sure about the box size in which the product is to be shipped, packaging material and have to make sure if the product is not damaged.

Don’t miss to check!

Before moving to the package, make sure to check the product once with the order slip.

Once you are sure about the product, move ahead with a light packaging so that the weight of packaging does not add more to the shipping of the product.

And also make sure that the packaging of the product supports its efficient transportation.

5. Shipping

Shipping is the final and one of the most important steps of this process. Once the product is packed, it is now ready to be shipped to your customers.

Reports depict that 63% of customers buy more items if the delivery takes minimum time and has the option of free delivery.

Therefore, this process needs more tracking as you have to make sure that the right product goes to every customer without creating any hassle.

Successful shipping of products confirms that your process of warehouse management is right!

Make a right decision