15 Effective Inventory Management Techniques

A recent study which is done by the Warehousing Education and Research Council found when it surveyed the number of e-commerce companies that the main the reason why many companies face loss is due to a lack of inventory management. These companies doesn’t have effective inventory management techniques.

Inventory Management plays a vital role to run a successful business or company. Have you ever wondered how companies earn a great profit? There are many companies that face loss due to mismanaged inventory. Inventory management is essential for a business or company to be successful.

The clothing retailer H&M company has made it to the top with a $20.3 billion yearly sales. In a decade, retail giant Walmart has grown from $70 to $127 billion and dominating the whole market. This is all possible due to a solid inventory management.

If you want to remain competitive and profitable in the market then you need a cost-saving solid inventory management system that helps to boosts the profit of your business. There are also some companies which get a lot of sale and customers but cannot make a profitable business from it due to lack of inventory management.

Inventory is a placeholder for your money. Holding an inventory ties up with a lot of cash. That’s why it is very important to have good inventory management for growing a company. There are various inventory management techniques are available, and choosing the correct one can lead to providing the correct goods, at the correct amount, place, and time.

Here you will get some best techniques for inventory management. By implementing these inventory management techniques you can take your business at the next level. But before that lets us know more about inventory management and it’s importance.

Organizations from small as well as large businesses can make use of inventory management to manage their flow of goods properly.inventory management includes aspects like controlling and overseeing purchases from the suppliers as well as customers in order to maintain the storage of stocks and to control the amount of product for sale and order fulfillment. Business is useless without proper inventory management.

As per the research, the data came in front of us that about more than 43% of business owners don’t track their inventory. This is one of the reasons why many companies and businesses cannot grow even though they had a lot of demand in the business.

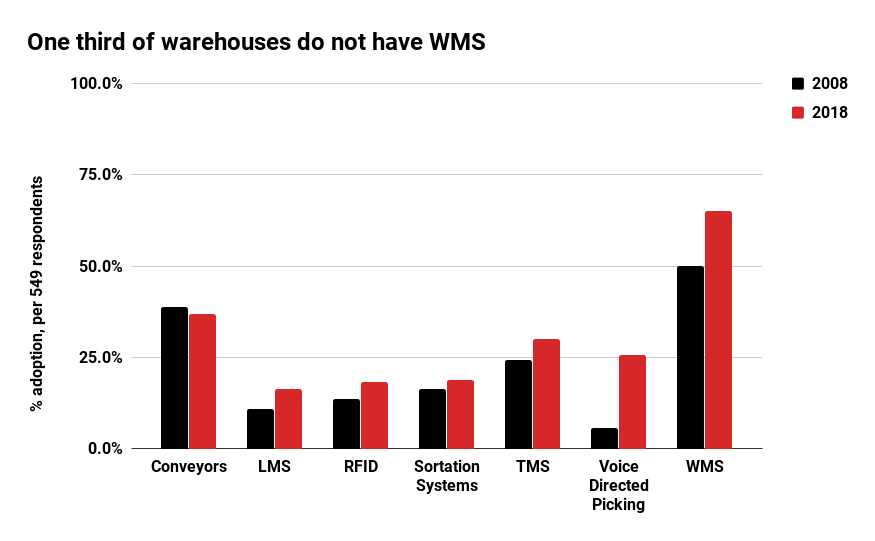

The survey by Supply Chain Dive shows that one-third of warehouses do not have a proper inventory and warehouse management system which is the main reason why companies are facing loss even after a lot of demand for products. So it is very important to have solid inventory management to run a successful business or company.

Inventory management uses many techniques to keep the right amount of goods on hand to fulfill customer demand and operate the business profitably.

15 Inventory Management Techniques for your business

Here are 15 Inventory management techniques that will definitely help to improve your inventory management and cash flow. Optimal inventory management varies for every company, but there are some general strategies by implementing any business can grow. We have listed here 15 techniques for great inventory management.

1) FIFO ( First in First Out) Method

It is a very important concept and widely used in inventory management by various businesses. It works on the basic principle that the product which comes first in the warehouse should be sold first. In this method First or the oldest stock will be used first.

This method ensures that the oldest stock will be used first which helps to reduce the cost of obsolete inventory. This inventory system is commonly used in several companies and warehouses. The FIFO method is applied to both warehouse management and accounting.

FIFO technique plays an important role in the warehouses that contain perishable products. It is widely used in the food and beverage industries. It helps in Effective management of your warehouse space.

2) Minimum Order Quantity ( MOQ)

Generally, suppliers used to supply the product in whatever quantity which you have ordered from them for your business. But there are many problems we have to face while order certain products from the suppliers because they have minimum order quantity criteria.

A minimum order quantity (MOQ) is the lowest or minimum amount of stock that a supplier is willing to sell or accept. If you are not able to purchase the minimum order quantity of a specific product, then the supplier won’t sell it to you.

The main purpose behind minimum order quantities is to allow suppliers to make more profits while getting rid of more inventory management.

Wholesalers generally don’t prefer doing business in such a way, but in many cases, wholesalers are forced to sell using MOQs because they’re forced to buy a minimum amount of stock from the manufacturer.

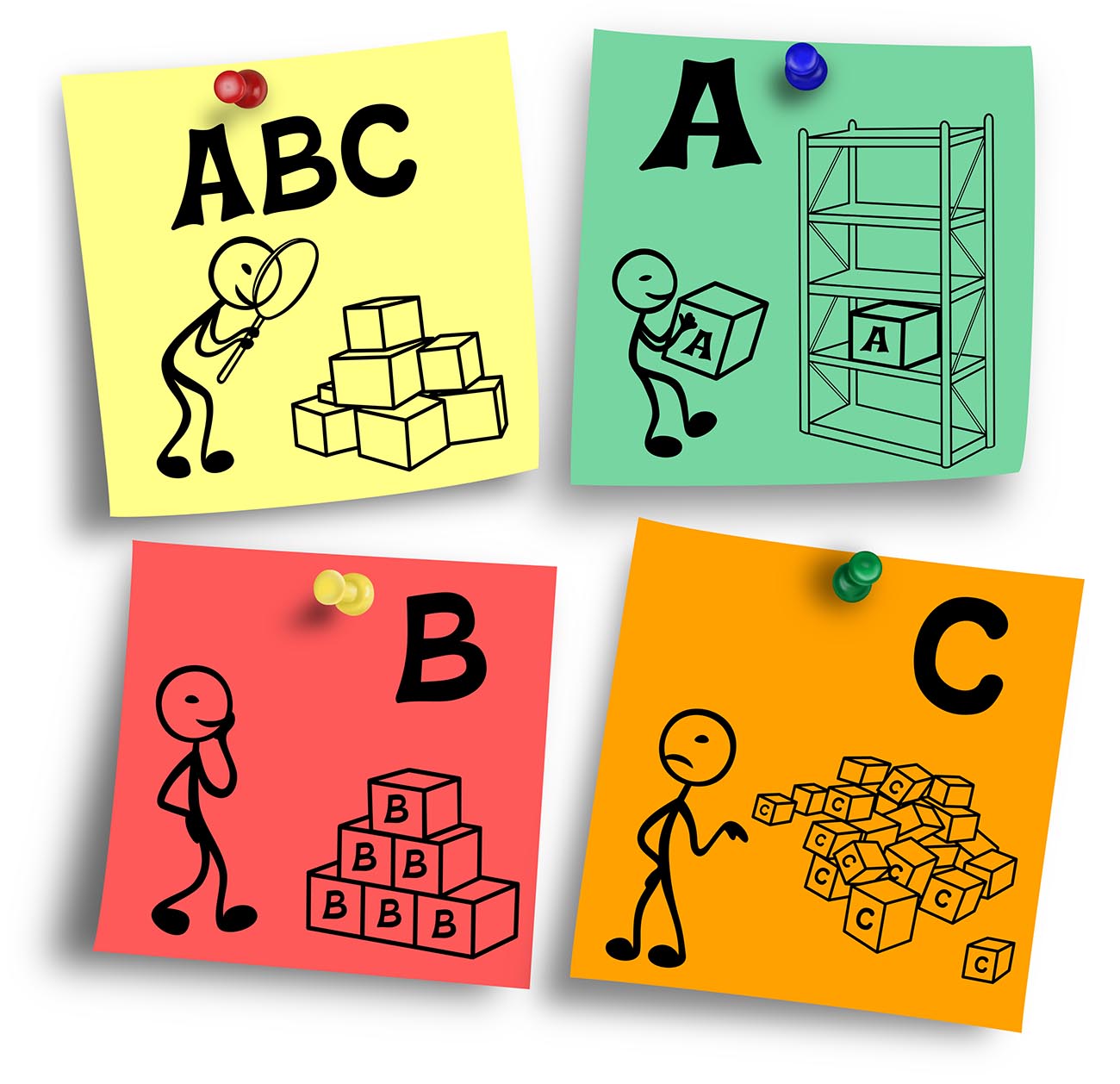

3) ABC Analysis

There are many products available in our inventory and it is obvious that we are more focused on the products which have more demand in the market and have high sales. But to manage the inventory effectively it is very necessary that we should give attention to each and every product.

For this Many businesses use the ABC Analysis technique which is the best method to efficiently manage your inventory. In this method, the products are getting categorized into different groups.

ABC analysis is an approach for classifying the products which are present in the inventory as per their consumption values. Consumption value is defined as the total value of an item that is consumed over a specified period of time.

ABC analysis is a method of analyzing which helps to categorized products into three categories: A, B, and C.

Category A

In this category, the products are of high-value but have a low frequency of sales. Such products required more attention because it consists of products which have more financial value.

Category B

In this category, the products are of low value but have a high frequency of sales. In this case, such products may require less attention because they are continuously moving because of high demand.

Category C

In this category, the products are of moderate value and of the moderate frequency of sales. But this also required some attention and financial assessment.

4) Safety Stock Inventory

It is the level of extra stock that is maintained to mitigate the risk of run-out for goods and raw materials due to uncertainties in the supply or demand. It plays an important role in order to avoid stock out and keep customer satisfaction at a high level.

safety stock inventory helps to keep your warehouse and supply chain running smoothly. The goal of safety stock inventory is to make sure that your customers will be satisfied and keep coming back to you.

Safety stock protects against unforeseen variations in supply and demand. In simple words, Safety stock is an additional quantity of products added in the inventory to reduce the risk that the product will be out of stock.

5) Centralize your Inventory

Centralized inventory is a method in which stock is kept in a single location. Businesses generally merge all their products into a single place to make inventory management easy.

Centralizing your inventory has a number of benefits for your business. One of the greatest benefits of Centralize inventory systems is operational efficiency.

Centralized inventory maybe sometimes changing demand. With stock in a single location, it can be difficult to fulfill orders when there’s been a spike in demand in a specific geographic region or weather makes fulfillment impossible from your single warehouse.

Centralize inventory is the key to the profitability of your business.

6)Batch Tracking

Batch Tracking is a method that is used to group and monitor a set of stock that has similar properties. This process is used for the efficient tracing of goods.

It gives you detailed information about the product from raw material to finished goods. It helps you to know where it comes from, and where it went.

There are several benefits of batch tracking like:

- It helps to improve relationships with suppliers.

- It helps to identify which products are going to be expired.

- It has fewer accounting errors.

Batch tracking allows insight into the quality of your finished goods by tracking the raw materials of your suppliers. This identifying your best and worst suppliers which helps you to decide the right suppliers.

7) Dropshipping

It is a very simple method in which there is the direct delivery of the goods from the manufacturer to the customer.

Dropshipping is a supply chain management that allows businesses to reduce their inventory costs by not holding any inventory. It is one of the best inventory management techniques.

It is a very simple method in which we first receive an order then we have to forward it to the supplier and the. The supplier fulfills the order.

There are several benefits of using the Dropshipping technique for inventory management:

- One of the greatest advantages of Dropshipping is that we don’t have to invest a huge amount of money. It requires very little capital.

- Dropshipping required fewer overheads Because we don’t have to invest in purchasing inventory or managing a warehouse.

- Nowadays, dropshipping business can be run from anywhere. As long as you can communicate with suppliers and customers easily, you can run your business from anywhere.

8)Managing Relationships

It is one of the most important factors for running a successful business. A good relationship is very important in business. It is about clear, proactive communication.

It is very that you should have a strong relationship with the supplier to run your business effectively. This will be helpful to you for minimum order quantities. You can ask your supplier for a minimum order quantity so that you don’t have to carry much inventory. Good Relationships play a key role in order to build a successful business with maximum profit.

9)Contingency Planning

If you are running a business there are many uncertain inventory management issues are come in front of us and it is very difficult to fix or resolved those issues on time.

The problems which can arise during inventory management are as follows:-

- The product has a low frequency of sales takes the maximum space of your warehouse and there is no or little space available for products having a high frequency of sales.

- The unexpected rise in demand for a specific product and the product is out of stock.

- Cash flow turns to negative and it is not possible for you to pay for products which you needed.

- The manufacturer stops the delivery of the product without any prior notice. So it is necessary that you should identify the risk and make a solid contingency plan for better inventory management.

10)Regular Inventory Audit

An inventory audit is defined as the analytical procedure that helps to cross-checks the financial records which match inventory records, or the count of physical products.

It is very necessary to do regular auditing of the inventory in order to have an idea of stock in the warehouse. There are three ways by which the inventory can be tracked

- Spot Checking-It is the method in which the products are manually counted and cross Check with the actual data. This is generally done for high-value products.

- Physical Inventory-Many businesses prefer to do counting if the whole inventory only once at the end of the year because of the accounting and tax filling purpose.

11)Set par levels

A par level is defined as the minimum amount of a product that should have on hand of any business. This helps to meet the customer’s demand while also maintaining safety stock in the case of uncertain demand.

The par level is ideal for use Effective management.

If you track par levels in real-time it will help you to track which stocks are depleting faster than others and which products have less demand in the market. It will prompt proactive orders to replenish stock so you don’t run out.

If you don’t maintain par levels properly, you might find yourself in a situation where you cannot fulfill customer demands.The concept of par levels is helpful for warehouse managers and business owners for control of the inventory.

12)Prepare for different Seasonality

There is a massive change in the demand for the product as per the season. So it is very necessary for the business that you should be ready for the changes in customer demand in the market.

Seasonal inventory required stock which is in high demand during particular times. these periods of time often coincide with the different seasons, and companies need to be proactive in preparing for different demand during these key times.

Seasonal inventory can be unpredictable in the market. seasonal inventory can be a challenge to your inventory control plan, making it difficult to prepare for the changes in demand for various products in the market.

So it is necessary to forecast the demand of products from past data to achieve better inventory management.

13)Tracking your sales

Tracking sales and available inventory help in determining what you need to order. Using the point of sale and tracking programs can add to the expense but they will help you to ensure that your customers have what they want while you maintain the minimum amount of stock necessary.

It is very necessary to track inventory levels on time for proper supply chain and critical for e-commerce brands that want to scale up successfully in the market. If you do not properly track your inventory sales it will end up with frustrated customers, excessive inventory, obsolete inventory which is not good for your business.

A good inventory system will help in communicating with suppliers and making demand adjustments. Using an inventory tracking system is the most efficient inventory tracking technique as it helps in achieving better transparency and accuracy than other techniques.

14) Accurate Forecasting

For ideal inventory management requires accurate forecasting of the demands for different products. But the forecasting is not an easy task it requires deep study and analysis of the market. It depends on the various factors

Various Trends for different products in the market.

- The growth rate of the current year.

- The demand of customers for specific products.

- Guaranteed sales from contracts and subscriptions

- Seasonality and the overall economy

Demand forecasting goes beyond simple estimates of product demand, looking into complex patterns overtime to produce more accurate and timely predictions. Any organization will be able to better manage inventory, increase revenue only after proper inventory management and accurate forecasting of sales.

If you are running a business and want to scale up, then it is very important to investigate the efficiency of their inventory management and forecasting processes.

15) Lean manufacturing system

Lean manufacturing system is an inventory management technique that primarily consists of a set of tools, a philosophy, and a system. It aims to reduce waste, optimize production, and helps put the customer first.

- The lean manufacturing technique delivers the most valuable product to the customer.

- It undergoes a process of ensuring all of your value-adding steps flow smoothly without any delays or interruptions.

- It maps out the steps and processes required to manufacture high-value products.

- Lean thinking and process improvement is a core part of the company culture.

Lean inventory management is the calculated approach to increasing the value of a company inventory by identifying and eliminating waste which is left after the manufacturing of the products.

Conclusion

It is very necessary for wholesalers and businesses to focus on inventory management to run their business effectively and having a check on finance and accounts. If there is a lack of management you cannot efficiently get items to customers when they need them. Inventory management will help you to know which products are overstock, under stock, and out of stock. Inventory management helps to keep a check on the financial activities of the organizations.

Inventory management touches many parts of your business. This can lead to different types of problems in the business. Inventory management helps in faster shipping, within the warehouse. you can easily know that you have the inventory on hand to ship. You’ll have more control over your inventory and be able to track it over different locations.

So now it’s time to take control of your inventory by using the above inventory management techniques which will definitely stop you from losing money and make your business more profitable. eVanik gives you the capability to implement all the above mentioned techniques.